Bending

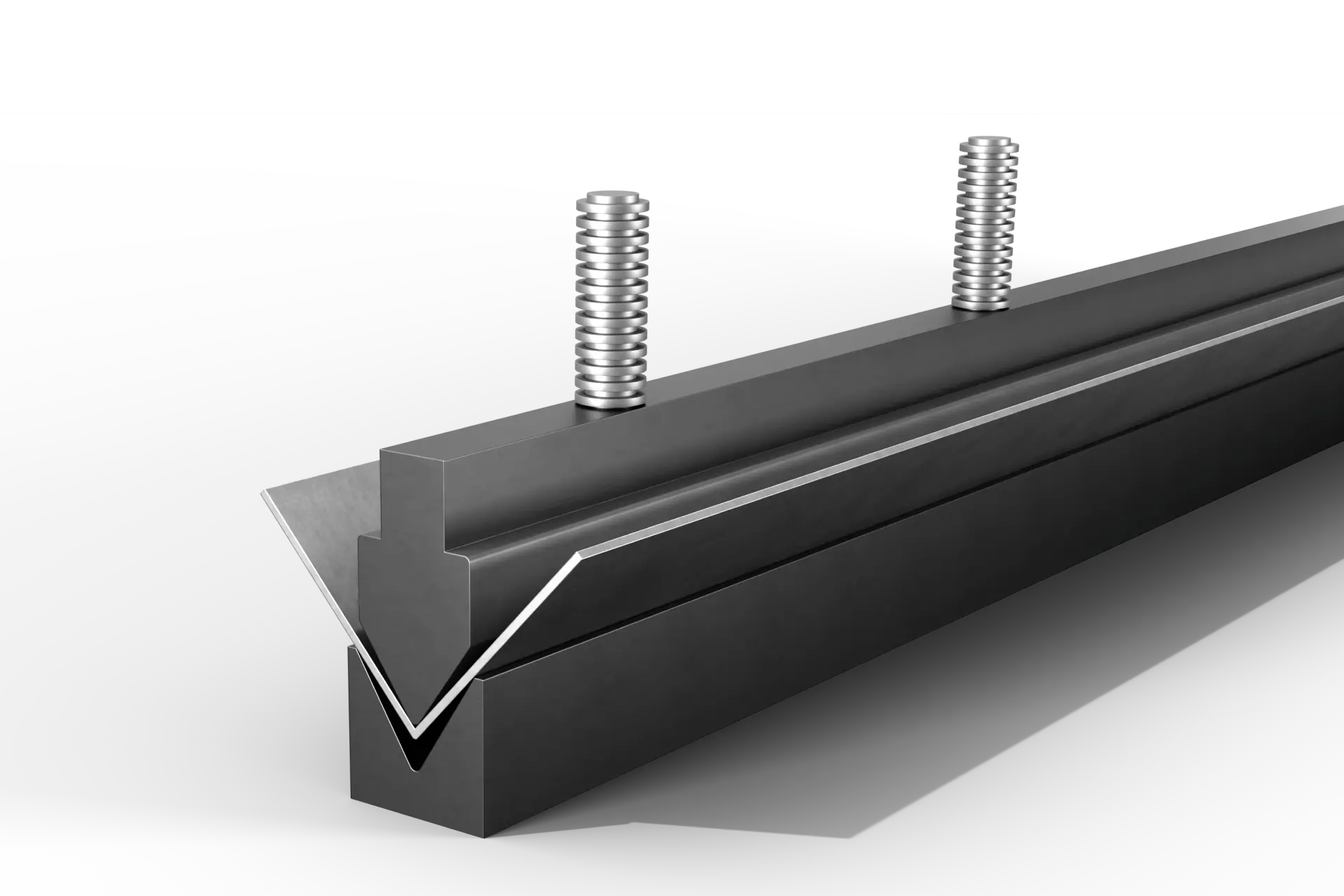

Sheet metal bending is a precise process in which we shape metal parts according to individual requirements. With advanced CNC press brakes and state-of-the-art measuring systems such as Laser Controlled Bending, we offer the highest quality and repeatability in our projects. Our versatile machinery allows us to bend sheet metal up to 8.3 meters in length and up to 15 mm in thickness, meeting the needs of both large-scale and individual orders.

Precision sheet metal bending at PG Group

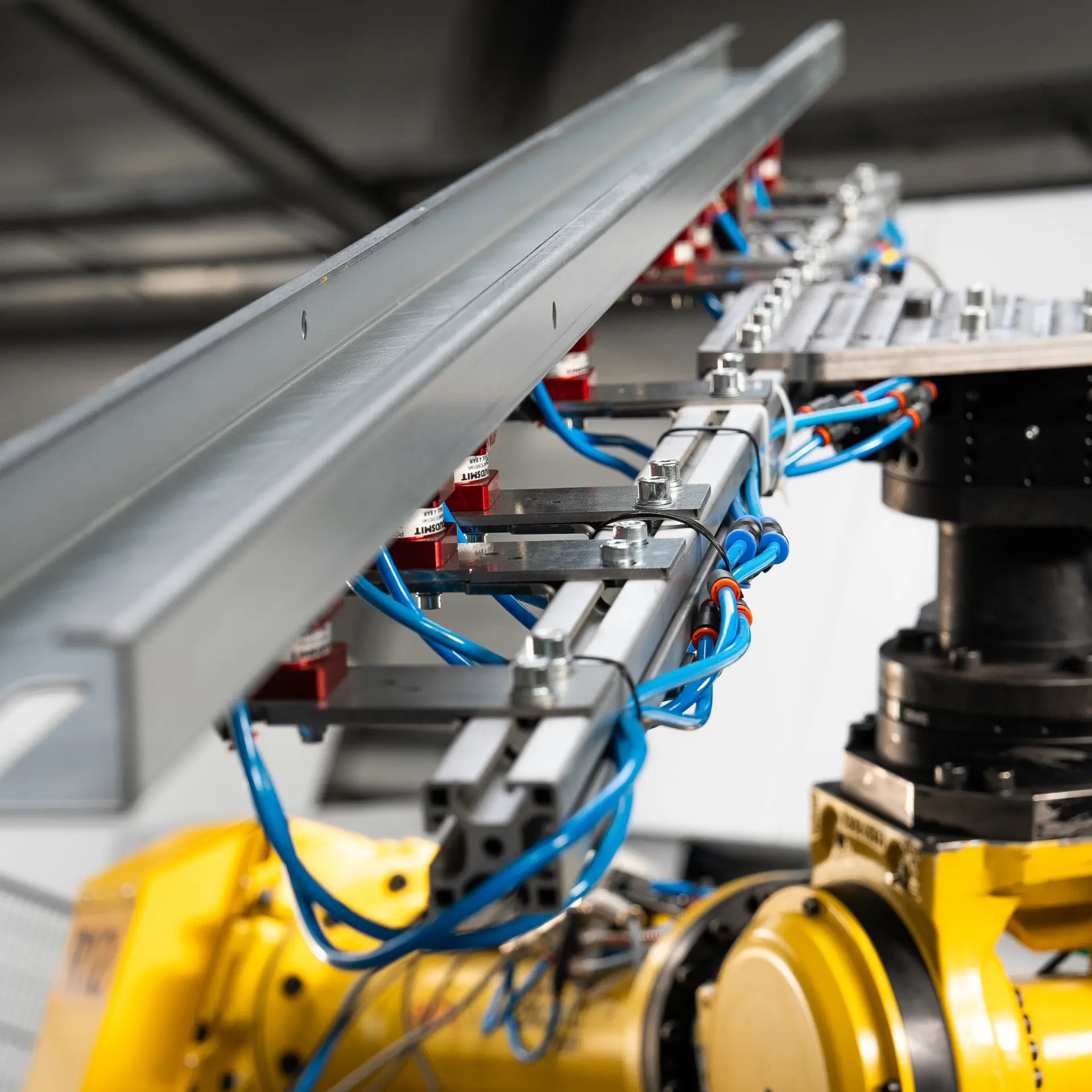

At PG Group, we offer comprehensive sheet metal bending services tailored to the individual needs of our customers. With our state-of-the-art CNC press brakes, we provide precise forming of parts up to 8.3 meters long and up to 15 mm thick. Our advanced measuring systems, such as Laser Controlled Bending (LCB) and automatic deflection compensation, guarantee the highest accuracy and repeatability of the bending process. The use of CNC technology allows us to implement even the most complex projects with full material integrity.

Feel free to contact us, we will be happy to prepare an offer tailored to your needs and answer all your questions.

Versatile machinery

We have a wide range of press brakes, such as the VarioPress 300- 80 with an impressive 3,000 kN clamping force and a bending length of up to 8,300 mm, and the TruBend 5230, which can form steel up to 15 mm thick with a clamping force of 2,300 kN. For more precise tasks, we use the TruBend 7036, which offers an accuracy of up to 0.002 mm when working on smaller parts. Thanks to the variety of our machines, we can efficiently execute both large production runs and unit projects with a high degree of complexity.

Innovative technology and quality

Our machines are equipped with advanced features, such as automatic measurement of bending angles and multi-touch 3D control systems, allowing for fast and precise execution of orders. Thanks to a flexible tooling system and the ability to work in tandem, we ensure ideal results even with very long parts. The use of modern technology minimizes the risk of errors and material waste, which translates into time and cost savings for our customers. At PG Group, we focus on quality and reliability in every implementation.