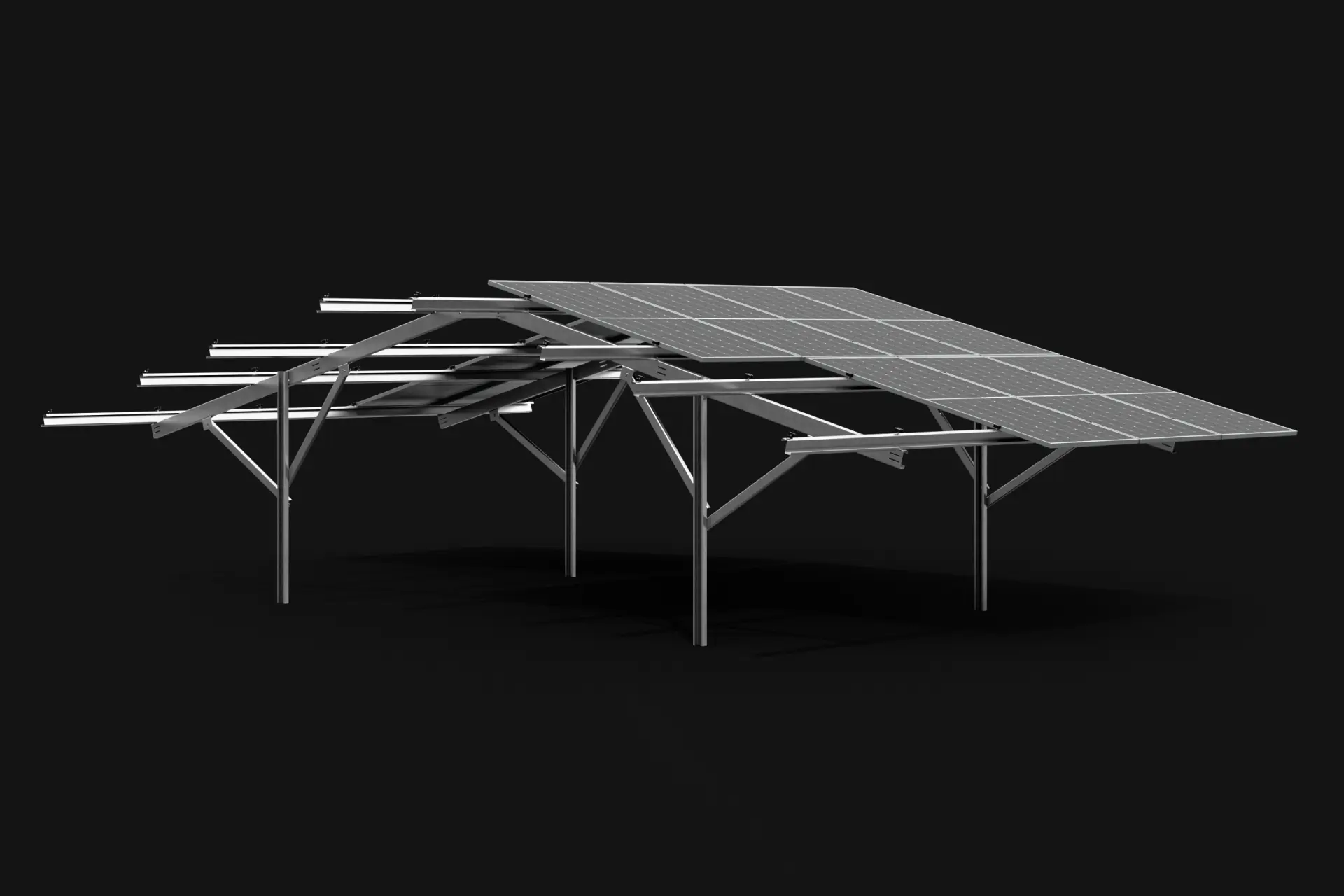

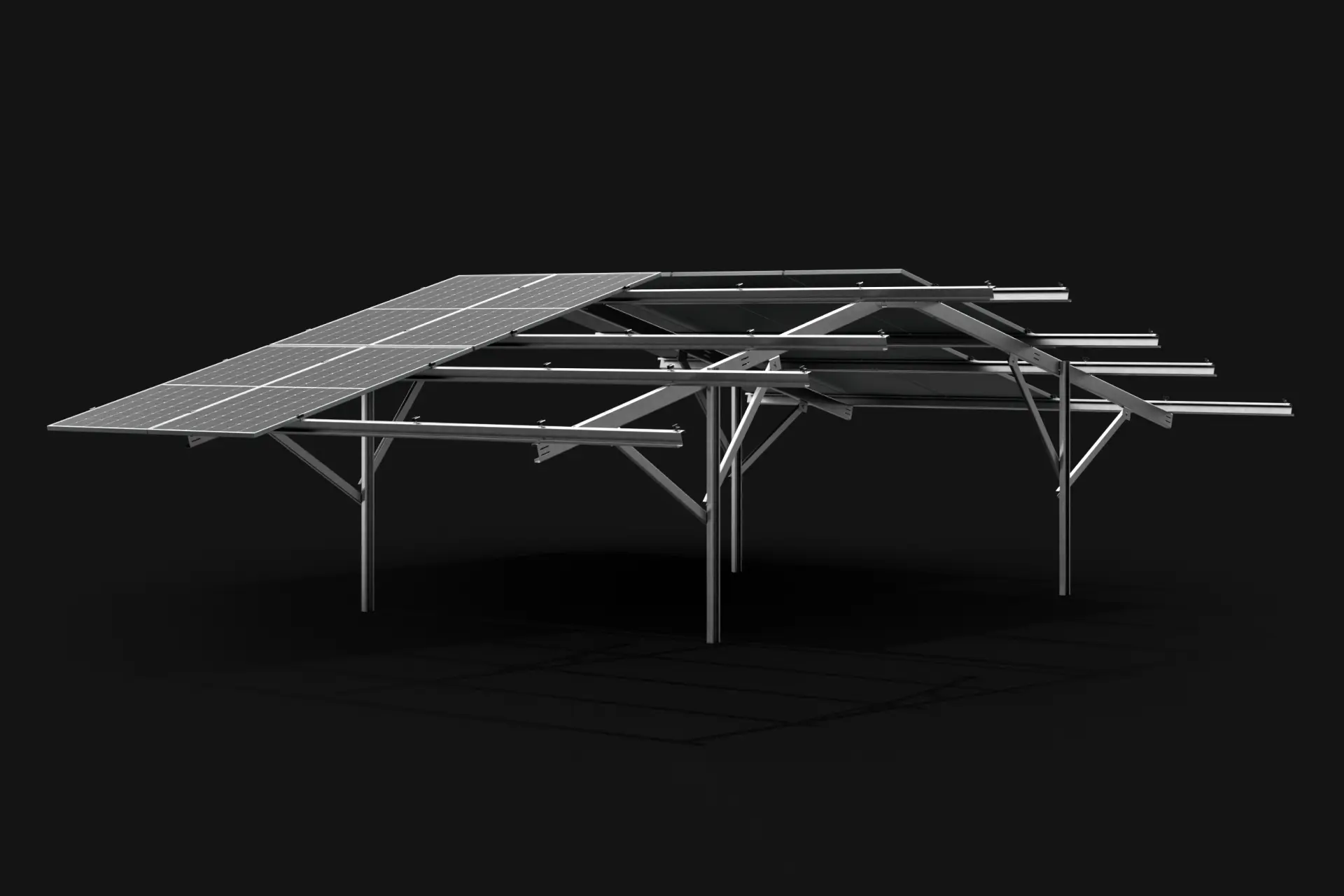

The EW2-V2 freestanding system for mounting monofacial panels is an “east-west” design with a vertical and double-row arrangement. The standard installation solution is driving into the ground using a pile driver. Depending on the terrain and project requirements, concrete-mounted footings, ballasting on the ground or in the ground, and piling with a retaining plate can also be used.

Depending on the client’s needs, the system can be designed with slope angles from 10° to 30°. The most commonly used material is S350GD structural steel and 310, 430 or 620 zinc-magnesium coatings. Such a combination guarantees the achievement of a warranty of up to 15 years. This makes our solutions a sustainable investment for years to come.

- No maintenance required

- Configurable design

- Easy and quick installation